Note

Go to the end to download the full example code.

Simulating a 1P3S Battery Pack Using the Battery Model#

Objective#

This example demonstrates a complete 1P3S battery pack simulation workflow comprising one parallel string and three cells in series using the NTGK (Newman-Tiedemann-Gu-Kim) electrochemical model utilizing PyFluent APIs. The goal is to model and analyze battery pack behavior under a constant 200 W discharge condition. This includes setting up active and passive zones, defining dual-path electrical conductivity using User-Defined Scalars (UDS), and applying convection cooling to simulate heat dissipation. The simulation aims to monitor key performance indicators such as pack voltage, maximum temperature, current flow, and heat generation over a 1500 second transient run, providing insights into thermal and electrical performance relevant to electric vehicle (EV) and energy storage system (ESS) design.

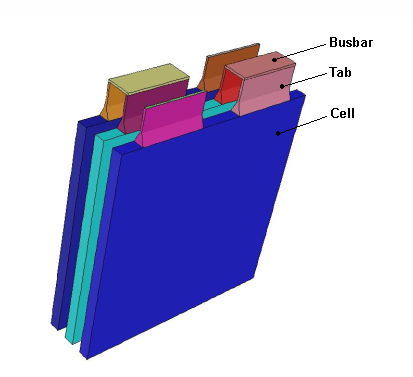

Problem Description#

Simulation of a 1P3S lithium-ion battery pack, consisting of three cells connected in series and no parallel branches, undergoing a constant 200 W discharge to represent a high-load condition. Each cell has a nominal capacity of 14.6 Ah, resulting in a total pack capacity of 14.6 Ah and a nominal voltage range of 10.8–12.6 V, corresponding to an average cell voltage of approximately 3.9 V. The discharge C-rate equates to about 1.17C, and the total energy of roughly 171 Wh means the discharge would last around 51 minutes (3060 seconds). The simulation model includes active zones for the electrochemical cells and passive zones representing conductive components such as tabs and busbars, with defined electrical and thermal material properties. The model also incorporates natural convection cooling with a heat transfer coefficient of 5 W/m²·K and an ambient temperature of 300 K, allowing for realistic thermal management analysis.

Import modules#

Note

Importing the following classes offers streamlined access to key solver settings, eliminating the need to manually browse through the full hierarchy of settings APIs structure.

import os

import ansys.fluent.core as pyfluent

from ansys.fluent.core import examples

from ansys.fluent.core.solver import (

Battery,

BoundaryConditions,

CellZoneConditions,

Contour,

Controls,

General,

Graphics,

Initialization,

Materials,

Mesh,

ReportDefinitions,

RunCalculation,

Solution,

Vector,

)

from ansys.fluent.visualization import GraphicsWindow, Monitor

Launch Fluent in solver mode#

solver = pyfluent.launch_fluent(

precision=pyfluent.Precision.DOUBLE,

mode=pyfluent.FluentMode.SOLVER,

)

Read mesh#

mesh_file = examples.download_file(

"1P3S_battery_pack.msh",

"pyfluent/battery_pack",

save_path=os.getcwd(),

)

solver.settings.file.read_mesh(file_name=mesh_file)

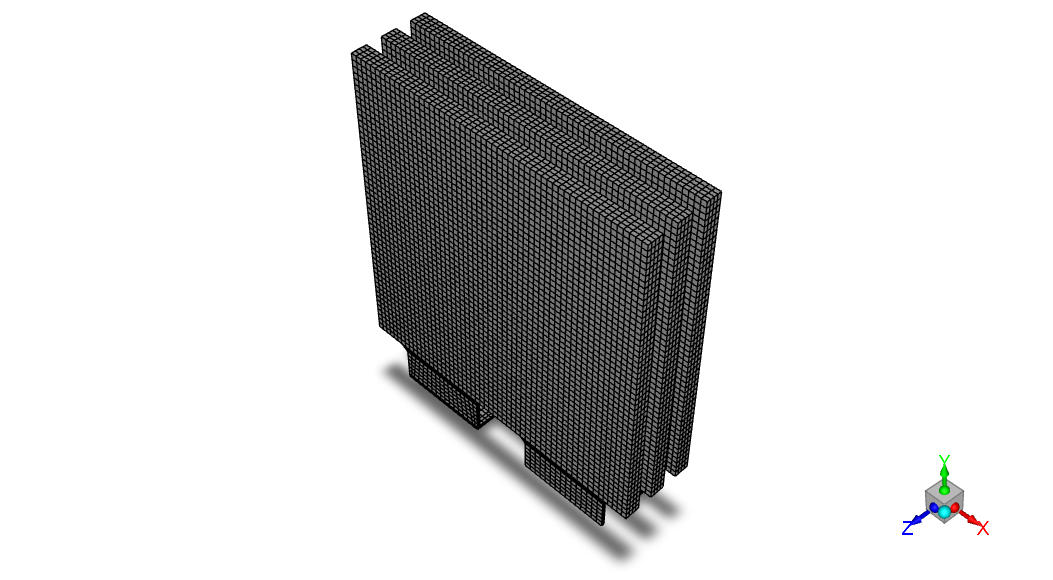

Display mesh#

graphics = Graphics(solver)

mesh = Mesh(solver, new_instance_name="mesh-1")

all_walls = mesh.surfaces_list.allowed_values()

graphics.picture.x_resolution = 650 # Horizontal resolution for clear visualization

graphics.picture.y_resolution = 450 # Vertical resolution matching typical aspect ratio

mesh.surfaces_list = all_walls

mesh.options.edges = True

mesh.display()

graphics.picture.save_picture(file_name="battery_pack_1.png")

Solver settings#

solver_general_settings = General(solver)

solver_general_settings.solver.time = "unsteady-1st-order"

Enable Battery Model (NTGK/DCIR)#

Note

Using wildcards (*, ?, |, etc.) instead of explicit zone lists makes the setup more flexible and scalable. For example:

cell_*→ selects all zones starting withcell_(e.g.,cell_1,cell_2, …)*bar*|*tabzone*→ selects zones containing eitherbarortabzone(e.g.,bar1,n_tabzone_1,…)

battery_model = Battery(solver)

battery_model.enabled = True

battery_model.echem_model = "ntgk/dcir"

battery_model.eload_condition.eload_settings.eload_type = "specified-system-power"

battery_model.eload_condition.eload_settings.power_value = 200 # W (Total pack power)

# Conductive zones

battery_model.zone_assignment.active_zone = "cell_*" # Active cells

battery_model.zone_assignment.passive_zone = "*bar*|*tabzone*" # Bars zones + tab zones

# External electrical contacts

battery_model.zone_assignment.negative_tab = ["tab_n"] # Negative terminal

battery_model.zone_assignment.positive_tab = ["tab_p"] # Positive terminal

Define materials#

materials = Materials(solver)

# Active material (cells): conductivity via UDS-0 and UDS-1

materials.solid.create("e_material")

materials.solid["e_material"] = {

"chemical_formula": "e",

"thermal_conductivity": {"value": 20}, # W/(m·K)

"uds_diffusivity": {

"option": "defined-per-uds",

"uds_diffusivities": {

"uds-0": {"value": 1000000}, # S/m (Electronic conductivity)

"uds-1": {"value": 1000000}, # S/m (Ionic conductivity)

},

},

}

# Passive material (busbars & tabs): high constant conductivity

materials.solid.create("busbar_material")

materials.solid["busbar_material"] = {

"chemical_formula": "bus",

"uds_diffusivity": {

"option": "value",

"value": 3.541e7, # S/m (Copper-like conductivity)

},

}

Assign materials to cell zones#

cell_zone_conditions = CellZoneConditions(solver)

# Assign e_material to cell_1

cell_zone_conditions.solid["cell_1"] = {"general": {"material": "e_material"}}

# Copy to cell_2 and cell_3

cell_zone_conditions.copy(from_="cell_1", to="cell_*")

# Assign busbar_material to bar1

cell_zone_conditions.solid["bar1"] = {"general": {"material": "busbar_material"}}

# Copy to all passive zones

cell_zone_conditions.copy(from_="bar1", to="*bar*|*tabzone*")

# '*bar*' matches any zone containing 'bar',

# '|*tabzone*' matches any zone containing 'tabzone' → OR logic

Boundary conditions#

conditions = BoundaryConditions(solver)

# Convection on wall-cell_1

conditions.wall["wall-cell_1"] = {

"thermal": {

"thermal_condition": "Convection",

"heat_transfer_coeff": {"value": 5}, # W/(m²·K)

}

}

# Copy to all other walls (tabs, busbars, cells)

conditions.copy(from_="wall-cell_1", to="wall*")

Define solution controls and monitors#

controls = Controls(solver)

# Disable flow and turbulence equations

controls.equations = {

"flow": False,

"kw": False,

}

solution = Solution(solver)

solution.monitor.residual.options.criterion_type = (

"none" # No automatic convergence check

)

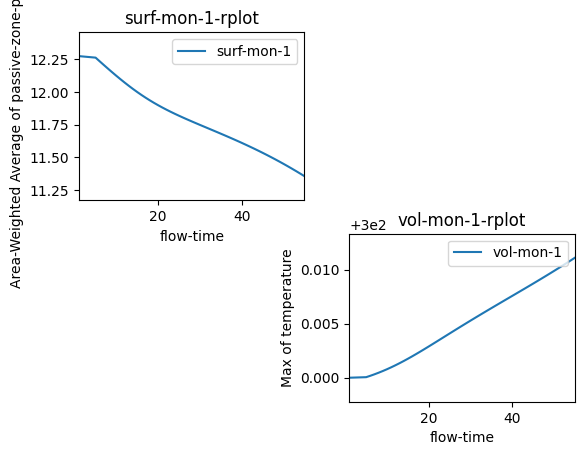

Define report definitions#

definitions = ReportDefinitions(solver)

# Surface report: voltage at positive tab (area-weighted average)

definitions.surface["voltage_surface_areaavg"] = {

"report_type": "surface-areaavg",

"field": "passive-zone-potential",

"surface_names": ["tab_p"],

"create_report_file": True,

"create_report_plot": True,

}

# Format plot axes

report_plot = solver.settings.solution.monitor.report_plots[

"voltage_surface_areaavg-rplot"

]

report_plot.axes.x.number_format.precision = 0 # Integer time steps

report_plot.axes.y.number_format.precision = 2 # 2 decimal places for voltage

# Volume report: maximum temperature in all cell zones

definitions.volume["volume_max_temp"] = {

"report_type": "volume-max",

"field": "temperature",

"cell_zones": "*cell|*bar*|*tabzone*",

"create_report_file": True,

"create_report_plot": True,

}

# Format plot axes

report_plot_1 = solver.settings.solution.monitor.report_plots["volume_max_temp-rplot"]

report_plot_1.axes.x.number_format.precision = 0

report_plot_1.axes.y.number_format.precision = 2

Initialize solution#

initialize = Initialization(solver)

initialize.standard_initialize()

Transient controls#

Transient_controls = solver.settings.solution.run_calculation.transient_controls

Transient_controls.time_step_count = 50 # Number of time steps

Transient_controls.time_step_size = 30 # s (30 s per step)

calculation = RunCalculation(solver)

calculation.calculate() # Run transient simulation

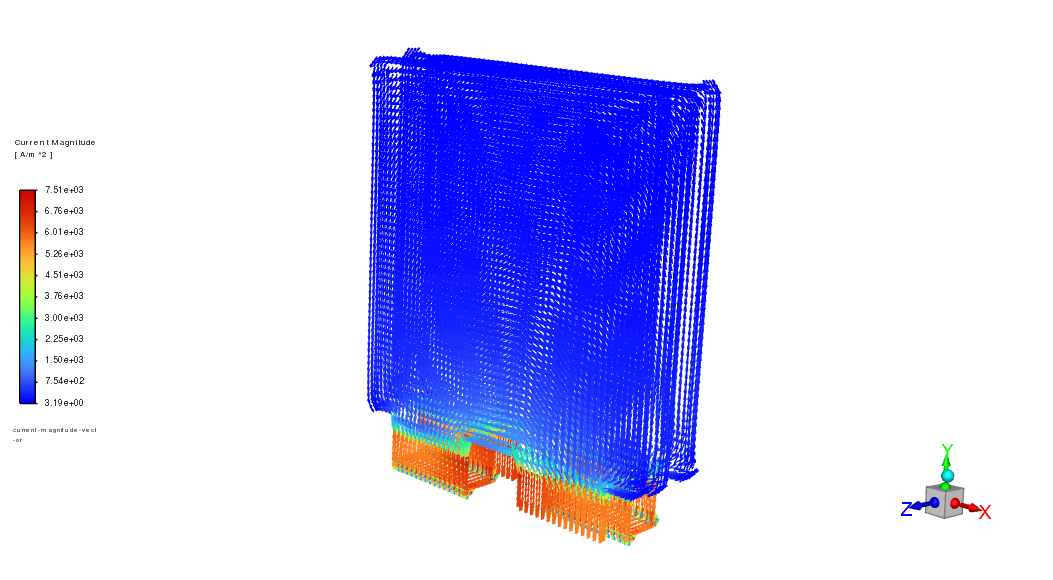

Post-processing#

# Current density vector plot

vector = Vector(solver, new_instance_name="current-magnitude-vector")

vector.vector_field = "current-density-j" # A/m² (Current density vector)

vector.field = "current-magnitude" # A/m² (Magnitude for coloring)

vector.surfaces_list = ["tab_n", "tab_p", "wall*"]

vector.options.vector_style = "arrow"

vector.options.scale = 0.03 # Scale factor for visibility

vector.vector_opt.fixed_length = True # Uniform arrow length

vector.display()

graphics.views.restore_view(view_name="isometric")

graphics.picture.save_picture(file_name="battery_pack_2.png")

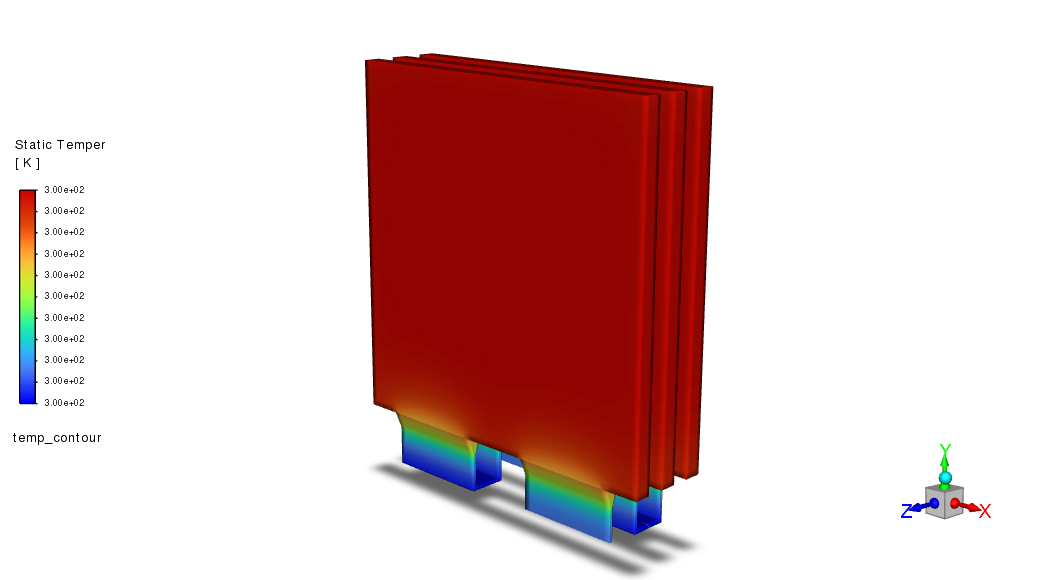

# Temperature contour

temp_contour = Contour(solver, new_instance_name="temp_contour")

temp_contour.field = "temperature" # K

temp_contour.surfaces_list = ["tab_n", "tab_p", "wall*"]

temp_contour.colorings.banded = True

temp_contour.display()

graphics.views.restore_view(view_name="isometric")

graphics.picture.save_picture(file_name="battery_pack_3.png")

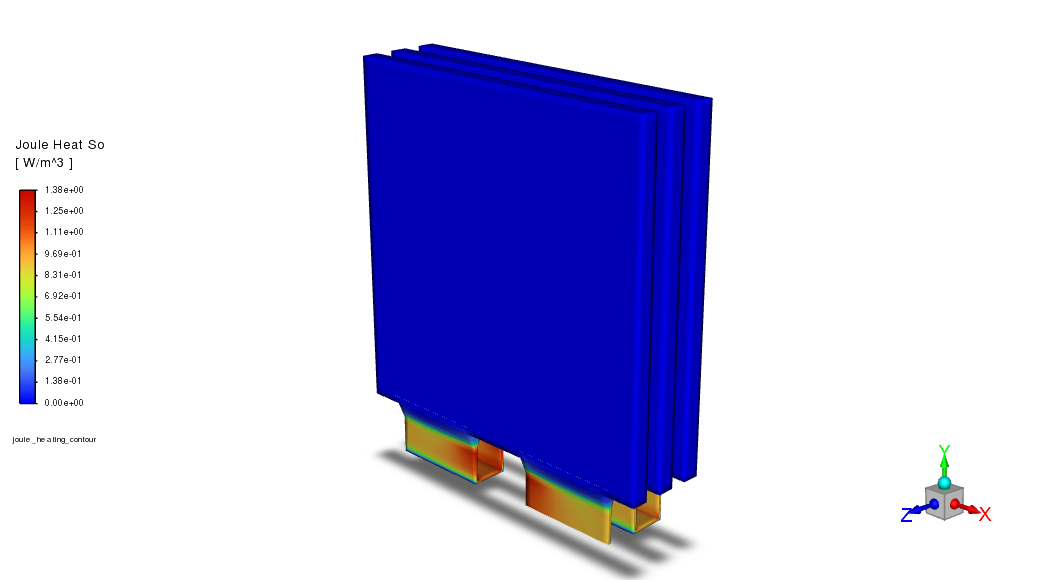

# Joule heat source contour

joule_contour = Contour(solver, new_instance_name="joule_heating_contour")

joule_contour.field = "battery-joule-heat-source" # W/m³

joule_contour.surfaces_list = ["tab_n", "tab_p", "wall*"]

joule_contour.colorings.banded = True

joule_contour.display()

graphics.views.restore_view(view_name="isometric")

graphics.picture.save_picture(file_name="battery_pack_4.png")

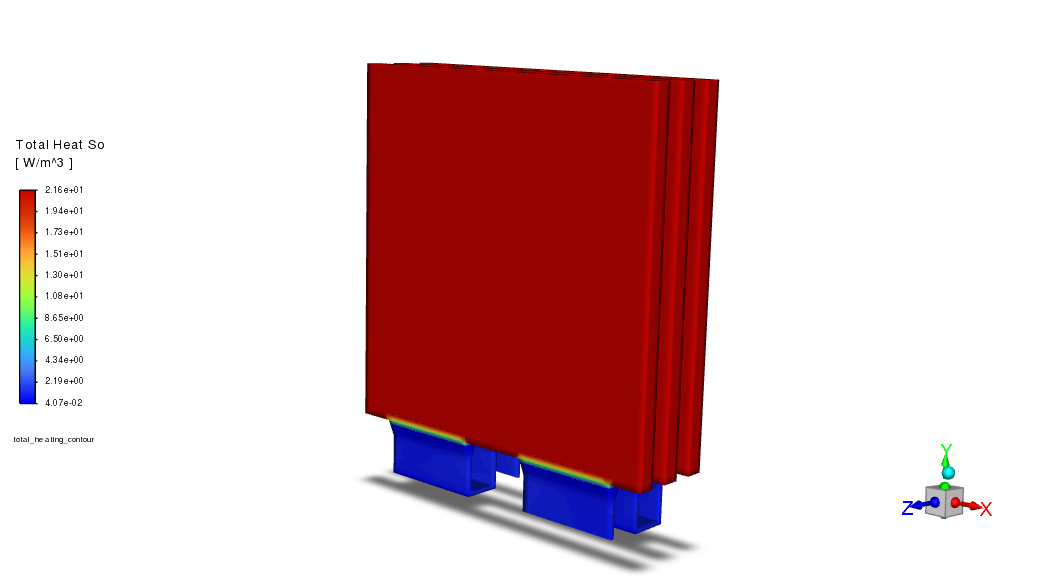

# Total heat source contour

total_heat_contour = Contour(solver, new_instance_name="total_heating_contour")

total_heat_contour.field = "total-heat-source" # W/m³ (Joule + reaction heat)

total_heat_contour.surfaces_list = ["tab_n", "tab_p", "wall*"]

total_heat_contour.colorings.banded = True

total_heat_contour.display()

graphics.views.restore_view(view_name="isometric")

graphics.picture.save_picture(file_name="battery_pack_5.png")

Display monitor plots#

plot_window = GraphicsWindow(solver)

voltage_rplot = Monitor(solver, monitor_set_name="voltage_surface_areaavg-rplot")

plot_window.add_plot(voltage_rplot, position=(0, 0))

temp_rplot = Monitor(solver, monitor_set_name="volume_max_temp-rplot")

plot_window.add_plot(temp_rplot, position=(1, 1))

plot_window.renderer = "matplotlib"

plot_window.show()

Save case and data#

solver.settings.file.write_case_data(file_name="1P3S_Battery_Pack")

Close Fluent#

solver.exit()

Summary#

This example provides a complete and reproducible PyFluent workflow for simulating a multi-cell battery pack using the Battery Model with the NTGK sub-model. It demonstrates how to set up active and passive zones, apply constant power discharge, use UDS-based dual-path conductivity, and monitor voltage and temperature behavior during operation. It serves as a template for battery pack analysis, applicable to designs ranging from small modules to full EV packs.

References:#

[1] Simulating a 1P3S Battery Pack Using the Battery Model, Ansys Fluent documentation.