Note

Go to the end to download the full example code.

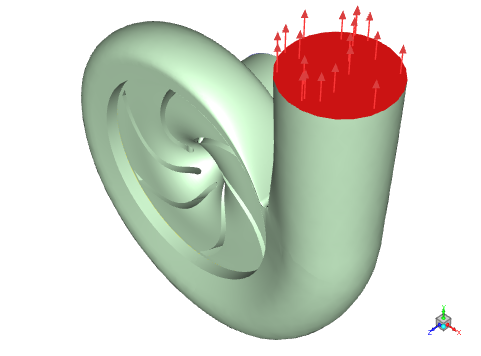

Impeller-Volute simulation using the Frozen Rotor Approach#

Objective#

This example demonstrates how to set up a CFD simulation of an impeller and volute using the frozen rotor approach. The frozen rotor approach is a technique used in computational fluid dynamics (CFD) to simulate the flow around rotating machinery, such as pumps, turbines, and compressors. In this approach, the rotor is treated as a stationary component, while the surrounding fluid is allowed to move. This allows for a more efficient simulation of the flow field, as the rotor’s motion does not need to be explicitly modeled. The frozen rotor approach is particularly useful for simulating steady-state flows, where the rotor’s motion is constant. By using this approach, engineers can obtain accurate predictions of the flow field and performance characteristics of rotating machinery without the need for complex and computationally expensive simulations.

Outline#

# The example demonstrates the following:

# *Overview & Problem description

# *Launching Fluent in solver mode.

# *Downloading a mesh files from the examples repository.

# *Initial setup

# *Mesh configuration

# *Model selection & Material definition

# *Defining cell zone conditions & boundary conditions

# *Turbomachinery configuration

# *Solver settings

# *Report definitions

# *Initialization

# *Running the simulation

# *Post-processing the results

# *Visualizing the results

# *Saving the case file

# *Closing the solver

Import required libraries/modules#

import math

import os

import ansys.fluent.core as pyfluent

from ansys.fluent.core import examples

Download the mesh file#

# Download the mesh file from the examples repository

# Impeller and volute mesh files

impeller_mesh = examples.download_file(

"impeller.msh.h5",

"pyfluent/examples/pump-volute",

save_path=os.getcwd(),

)

volute_mesh = examples.download_file(

"volute.msh.h5",

"pyfluent/examples/pump-volute",

save_path=os.getcwd(),

)

Define Constants#

density_water = 998.2 # kg/m^3

viscosity_water = 0.001002 # kg/(m.s)

g = 9.81 # m/s^2

# Impeller speed

impeller_speed = 1450 # rpm

# Convert to rad/s

impeller_speed_rad = impeller_speed * 2 * math.pi / 60 # rad/s

Launch Fluent with solver mode and print Fluent version#

solver_session = pyfluent.launch_fluent(

mode="solver",

processor_count=4,

cleanup_on_exit=True,

)

print(solver_session.get_fluent_version())

Read, append the mesh files#

# Read Impeller mesh file

solver_session.settings.file.read_mesh(file_name=impeller_mesh)

# Append Volute mesh file

solver_session.settings.mesh.modify_zones.append_mesh(file_name=volute_mesh)

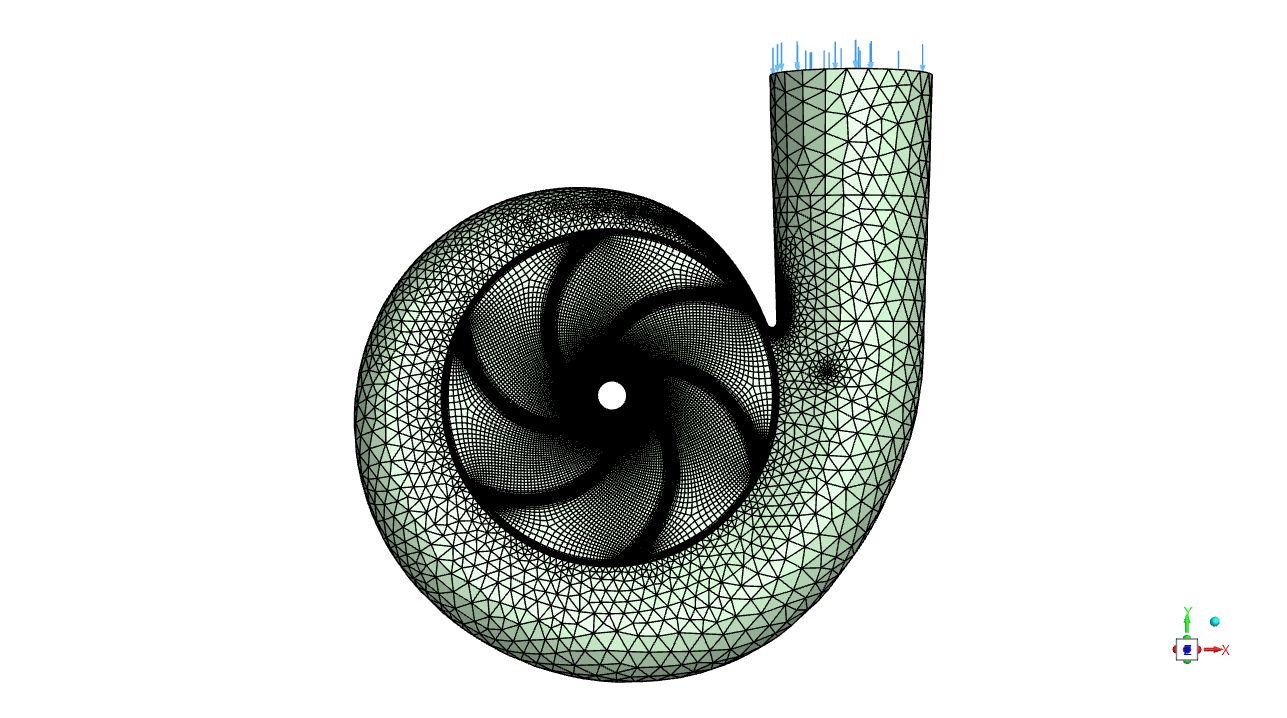

Display the mesh#

# Access the graphics object

graphics = solver_session.settings.results.graphics

# Create a mesh object and configure its settings

mesh_object = solver_session.settings.results.graphics.mesh.create(name="mesh-1")

mesh_object.surfaces_list = [

"inlet",

"mass-flow-inlet-11",

"interface-impeller-outlet",

"interface-volute-inlet",

"blade",

"impeller-hub",

"impeller-shroud",

"inblock-hub",

"inblock-shroud",

"volute-inlet-wall",

"volute-wall",

]

mesh_object.options.edges = True

# Set the hardcopy format for saving the image

graphics.picture.driver_options.hardcopy_format = "png"

graphics.views.restore_view(view_name="front")

mesh_object.display()

graphics.views.auto_scale()

graphics.picture.save_picture(

file_name="pump-volute-mesh.png",

)

Set the unit for angular velocity, rad/s to rev/min#

solver_session.settings.setup.general.units.set_units(

quantity="angular-velocity", units_name="rev/min"

)

Define the Viscous Model#

# Models setting

viscous = solver_session.settings.setup.models.viscous

viscous = solver_session.settings.setup.models.viscous

viscous.model = "k-omega"

viscous.k_omega_model = "sst"

Define Materials#

solver_session.settings.setup.materials.database.copy_by_name(

type="fluid", name="water-liquid"

)

Define Cell Zone Conditions#

impeller_cell_zone = solver_session.settings.setup.cell_zone_conditions.fluid[

"impeller"

]

impeller_cell_zone.general.material = "water-liquid"

impeller_cell_zone.reference_frame.reference_frame_axis_origin = [0, 0, 0]

impeller_cell_zone.reference_frame.reference_frame_axis_direction = [0, 0, 1]

impeller_cell_zone.reference_frame.frame_motion = True

# impeller rotation

impeller_cell_zone.reference_frame.mrf_omega.value = impeller_speed_rad

# Volute Cell Zone Conditions

volute_cell_zone = solver_session.settings.setup.cell_zone_conditions.fluid["volute"]

volute_cell_zone.general.material = "water-liquid"

# Boundary Conditions

# impeller hub

impeller_hub = solver_session.settings.setup.boundary_conditions.wall[

"impeller-hub"

].momentum

impeller_hub.wall_motion = "Moving Wall"

impeller_hub.relative = True

impeller_hub.velocity_spec = "Rotational"

# inblock-shroud

inblock_shroud = solver_session.settings.setup.boundary_conditions.wall[

"inblock-shroud"

].momentum

inblock_shroud.wall_motion = "Moving Wall"

inblock_shroud.relative = False

inblock_shroud.velocity_spec = "Rotational"

Define Boundary Conditions#

# Inlet Boundary Condition

pressure_inlet = solver_session.settings.setup.boundary_conditions.pressure_inlet[

"inlet"

]

pressure_inlet.momentum.supersonic_or_initial_gauge_pressure.value = -100

# It seems, need to change the boundary condition to mass flow outlet

solver_session.settings.setup.boundary_conditions.set_zone_type(

zone_list=["mass-flow-inlet-11"], new_type="mass-flow-outlet"

)

# Outlet Boundary Condition

mass_flow_outlet = solver_session.settings.setup.boundary_conditions.mass_flow_outlet[

"mass-flow-inlet-11"

]

mass_flow_outlet.momentum.mass_flow_rate.value = 90 # kg/s

# Create a turbo interfaces

# enable the turbo models

solver_session.settings.setup.turbo_models.enabled = True

impeller_volute_interface = (

solver_session.settings.setup.mesh_interfaces.turbo_create.create(

adjacent_cell_zone_1="impeller",

adjacent_cell_zone_2="volute",

mesh_interface_name="imp-volute-interface",

turbo_choice="No-Pitch-Scale",

zone1="interface-impeller-outlet",

zone2="interface-volute-inlet",

)

)

Define Solver Settings#

methods = solver_session.settings.solution.methods

methods.spatial_discretization.gradient_scheme = "green-gauss-node-based"

methods.high_order_term_relaxation.enable = True

Define Named Expressions#

pump_head = solver_session.settings.setup.named_expressions.create("head")

pump_head.definition = "(({p-out} - {p-in}) / (998.2 [kg/m^3] * 9.81[m/s^2]))"

pump_head.output_parameter = True

Define Report Definitions#

# Create a report definition

# p-out

outlet_pressure_report_def = (

solver_session.settings.solution.report_definitions.surface.create("p-out")

)

outlet_pressure_report_def.report_type = "surface-massavg"

outlet_pressure_report_def.surface_names = ["mass-flow-inlet-11"]

outlet_pressure_report_def.field = "total-pressure"

outlet_pressure_report_def.per_surface = False

outlet_pressure_report_plot = (

solver_session.settings.solution.monitor.report_plots.create("p-out-rplot")

)

outlet_pressure_report_plot.report_defs = "p-out"

outlet_pressure_report_file = (

solver_session.settings.solution.monitor.report_files.create("p-out-rfile")

)

outlet_pressure_report_file.report_defs = "p-out"

# p-in

inlet_pressure_report_def = (

solver_session.settings.solution.report_definitions.surface.create("p-in")

)

inlet_pressure_report_def.report_type = "surface-massavg"

inlet_pressure_report_def.surface_names = ["inlet"]

inlet_pressure_report_def.field = "total-pressure"

inlet_pressure_report_def.per_surface = False

# Pump Head

pump_head_report_def = (

solver_session.settings.solution.report_definitions.single_valued_expression.create(

"pump-head"

)

)

pump_head_report_def.definition = "head"

# report plot

pump_head_report_plot = solver_session.settings.solution.monitor.report_plots.create(

"pump-head-rplot"

)

pump_head_report_plot.report_defs = "pump-head"

# report file

pump_head_report_file = solver_session.settings.solution.monitor.report_files.create(

"pump-head-rfile"

)

pump_head_report_file.report_defs = "pump-head"

# p-blade

blade_pressure_report_def = (

solver_session.settings.solution.report_definitions.surface.create("p-blade")

)

blade_pressure_report_def.report_type = "surface-massavg"

blade_pressure_report_def.surface_names = ["blade"]

blade_pressure_report_def.field = "pressure"

blade_pressure_report_def.per_surface = False

Initialization and run solver#

initialization = solver_session.settings.solution.initialization

initialization.reference_frame = "absolute"

initialization.hybrid_init_options.general_settings.initialization_options.initial_pressure = (

True

)

initialization.hybrid_initialize()

# Run calculation settings

run_calculation = solver_session.settings.solution.run_calculation

run_calculation.pseudo_time_settings.time_step_method.time_step_size_scale_factor = 10

run_calculation.iter_count = 200

# Write the case file

solver_session.settings.file.write(

file_type="case", file_name="pump_voulte_setup.cas.h5"

)

# Run the calculation

run_calculation.calculate()

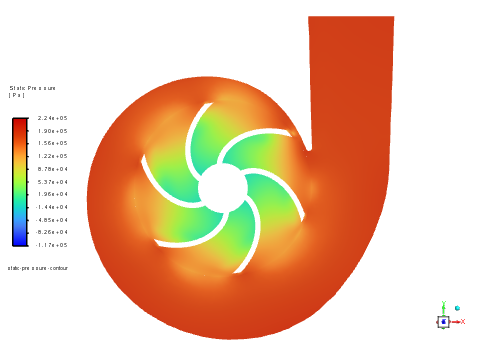

Post-Processing Workflow#

# Create a mid-plane surface at z = -0.015 m

z_mid_plane = solver_session.settings.results.surfaces.plane_surface.create(

name="z_mid_plane"

)

z_mid_plane.method = "xy-plane"

z_mid_plane.z = -0.015

z_mid_plane.display()

# Define the contour for static pressure

pressure_contour = solver_session.settings.results.graphics.contour.create(

name="static-pressure-contour"

)

pressure_contour.field = "pressure"

pressure_contour.surfaces_list = ["z_mid_plane"]

# Display the contour and save the image

graphics.views.restore_view(view_name="front")

pressure_contour.display()

graphics.views.auto_scale()

graphics.picture.save_picture(file_name="static-pressure-contour.png")

Save the case file#

solver_session.settings.file.write(

file_type="case-data", file_name="pump_volute_setup_solved.cas.h5"

)

Close the session#

solver_session.exit()

References#

[1] Ansys Fluent User’s Guide, Release 2025R1